▪ Let’s get the Lead-in of AUTOMOTIVE TEXTILES

Globalization being the key theme, the 1980s marked a significant era characterized by the commercial introduction of numerous new materials. The technical textiles, which include applications in medical, civil engineering & automotive fields are increasingly recognized as one of the most dynamic & promising sectors for the future of textile industry.

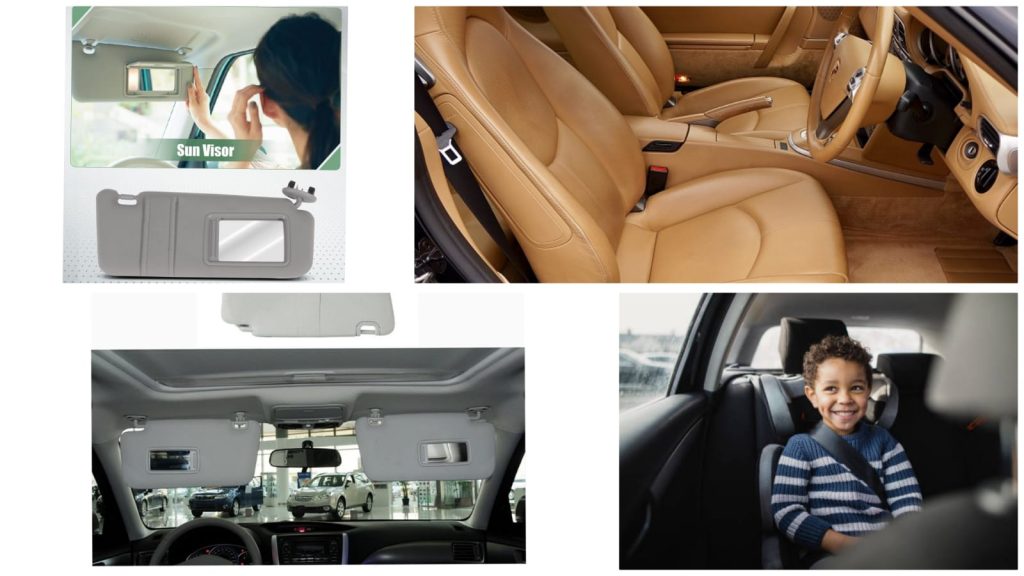

AUTOMOTIVE TEXTILES, a subset of technical textiles, encompass a wide range of fabric & material applications specifically designed for vehicles, such as interior trims, seats, carpets, door panels, headliners, airbags, seat belts, upholstery, filters & insulators.

Thegrowth in automotive textiles is highlighted for the explosive expansion in car production, which is 85.4 million globally.

▪ Wondering how was the early automobiles?

The first commercial car, designed by Karl Benz in 1885, used steel tubing and wood panels for the driver’s compartment. Early vehicles had simple wooden seats covered with leather scraps, fabric, or horse blankets. Leather and wood interiors were common until the 1950s when plastic moldings and synthetic fibers started being used, making car interiors resemble upscale furniture.

Synthetic leathers and vinyl were introduced for better durability and ease of cleaning. Nowadays, to reduce weight and emissions, new developments focus on using fabrics and fiber-based materials.

▪ Purpose & applications of AUTOMOTIVE TEXTILES

Improving vehicle comfort, high performance, reduce weight for better fuel efficiency & support sustainable practices.

1. Comforts – Flexible, warm & soft feel of seats, moist & odor resistant interior.

2. Decorative – Better interior, carpets.

3. Safety purpose – Seat belts, air bags.

4. Functional Textiles – Noise control fabrics, filters, battery separator.

▪ Used textiles in automative applications

1. SEAT COVER: Woven seat covers are made from cotton, vinyl, velvet & leather.

2. HELMET: Principal function of a helmet is to absorb the shock of a crash & put a stop to major injury to the brain, rather than preventing head & face crack. Internal layer- polystyrene or polypropylene foam, External layer- plastic, glass & other manmade fibers.

3. SUNVISORS: Located just above the windshield to increase visibility but blocking the sunlight from entering.

4. SEAT BELTS: Made from nylon yarn or polyester yarn.

5. INTERIOR CARPETS

6. CAR BODY COVERS: Used to cover cars

7. TYRE CORDS: A tire is a ring-shaped component that surrounds a wheel’s rim to transfer a vehicle’s load from the axle through the wheel to the ground and to provide traction on the surface traveled over. The belt system’s main function is to provide stability to the tire’s tread area, which contributes to wear, handling and traction

8. HEADLINERS: It’s a back up that is stick on to the interior roof of automobiles. Mostly made of tricotknit fabric.

9. AIR BAGS: A safety device aimed at preventing or minimizing injury to passengers when such an accident occurs.

▪ Conclusion

Automotive textiles are required to adhere to rigorous performance criteria, including strength, resistance to abrasion and heat, flame retardancy, and long-term durability. As automotive technology advances, these textiles play a key role in enhancing driving experiences & meeting evolving industry demands.

Writer Information

Nasratun Duha

Student, Textile Fashion & Design Department,

Bangladesh University of Textiles (BUTEX)

Campus Team Member, Textile Engineers Society (TES)