FLAX FIBRE

Fibre is the first textile raw material, generally characterized by flexibility, fineness, and high length to width ratio. A textile fibre is a fibre which can be converted into a yarn or fabric by interlacing, interloping using a variety of mechanical processes such as spinning, weaving, knitting and felting etc. There are two types of fibre.

1.Natural fibres 2. Man made fibres

Here the natural fibres are divided into three catagories.

1.Vegetable

2.Animal

3.Mineral

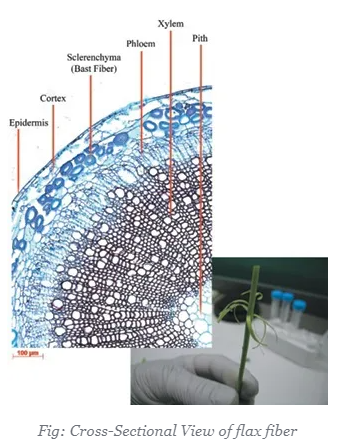

Bast fibre is the example of vegetable fibre. Flax fibre comes under the category of bast fibre and is extracted from the plant of the linseed/flax plant (Linum usitatissimum ).

This plant is popular for two reasons: one is flax fibre and another is linseed oil (As a finish to preserve wood products, As a nutritional supplement with many health benefits, As a polish and anti-rust agent for metals). The other common names of flax are- lin, linen, liner, lein and lan. It is classified as natural, cellulosic, bast and multicellular fibre. Flax is also name as linen. Linen is the term applied to the yarn spun from the flax fibre (Linen is a textile made from the fibers of the flax.

The main flax producing countries are France, Belgium, China, Netherlands, Canada .

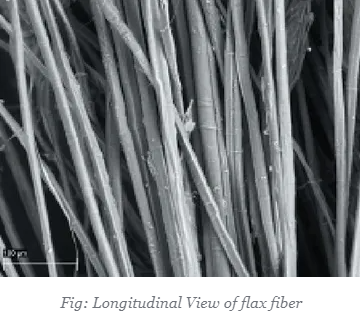

Microscopic View of Flax

PRODUCTION PROCESSES OF FLAX FIBRE

Cultivation : The most suitable soils for flax, are deep friable loams, and containing a large proportion of organic matter.

Harvesting : Flax is harvested for fiber production after approximately 100 days. The base of the plant will begin to turn yellow.

Threshing /rippling process of flax : Threshing is the process of removing the seeds from the rest of the plant. Typically the seed are removed by drawing handfuls of flax stems through the widely spaced teeth of a rippling comb.Different retting methods of flax fibre :bark are disintegrated or loosened by submerging the tied bundles in pool or ditches of water.

1. Dew retting: The crop is spread on the ground after pulling and left for several weeks. Wetting by dew and rain encourages fermentation. Dew retting tends to yield a dark colored fibre. It may be used in regions where water is in short supply.

2. Water retting (Tank retting): The bundles of flax fibre are placed in tanks of warm water where its lays for 5-8 days. If water temperature is kept at 800𝐅 , the retting process under these conditions takes 4 or 5 days. It is the Colder than 800F , it takes longer.

- Chemical retting: Chemicals like soda ash, oxalic soda and caustic soda in warm water or boiling water

in dilute H₂SO₄ solution are used in this retting.

Dressing the flax:

Dressing the flax is the process of removing the straw from the fibers. Dressing consists of three steps:

breaking, scutching, and hackling. The dressing is done as follows:

Breaking: The process of breaking breaks up the straw into short segments. To do it, take the bundles of

flax and untie them. Next, in small handfuls, put it between the beater of the breaking machine (a set of

wooden blades that mesh together) and beat it till the three or four inches that have been beaten

appear to be soft.

Scutching: The broken straw (consisting of the dry stalk/stem) is then subjected to the process known as

“scutching” which separates the unwanted woody matter from the fibre. This is done by scraping the

edge of the knife along the fibers and pull away pieces of the stalk.

Hackling (combing): After scutching, the first stage of fibre preparation is a combing process known as

hackling. It separates the long fibre from the shorter tow. A hackle is a bed of pins which are used to

comb the fibres for drawing and aligning purpose. The product of the hackling process is called line fibre,

with a length of 45 to 90 cm.

Flax fibre identification :

Microscopic test:

The ultimates are polygonal in cross-section, with thick walls and small lumina. Microscopically, the

fibers have dark dislocations that are roughly perpendicular to the long axis of the fiber

Chemical test:

Flax fibre is dissolved by 70% H2SO4 .

Properties of flax fibre :

- Length : The average length of flax fiber varies from 90-125 centimeters. The length of individual

fiber cells varies from 6-65 mm with an average diameter of 0.02mm. - Color: Brownish, grey, light, yellowish.

- Tensile strength: Tenacity varies from 6.5 to 8 gm/denier.

- Elongation: Elongation at break varies between 0.2%-3.2%

Specific gravity: 1.54

Moisture Regain: M.t12% (std.)

Effect of Acids: Flax fiber is damaged by strong acids.

Effects of Alkalis: Flax has a good resistance to alkalis.

Effect of heat: Highly resistant to decomposition up to 1200C. The fibers begin to discolor after crossing temperature limit. Heat conductance is good.

Chemical Composition of Flax Fibre is given below:

Cellulose (64-84)%

Hemicellulose (16-18)%

Lignin (0.6-5)%

Pectin (1.8-2)%

Waxes 1.5%

Writer information

Salman Sadik

Campus: AUST

Designation: TES General Member