Introduction:

The process of creating fabrics and other materials from fibers, known as textile production, has changed dramatically over time. Textile production techniques have changed over time, from hand-spun yarns of antique to highly advanced digitalized processes of today, bearing witness to human creativity and innovative thinking. The development of textile production processes, from simple hand tools to complex machinery and digital technology, is reflected in the advancement of human society as an entire organism. Let’s take a look back at the amazing development of textile manufacturing by traveling through time.

Early Textile Manufacturing Techniques:

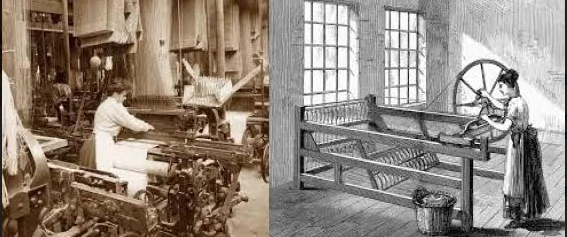

When textiles were first produced, quality of craftsmanship was crucial. The main techniques employed to produce textiles were hand spinning and weaving. Natural resources like plants and animals were the source of textiles like cotton, wool, and silk. Expert weavers would painstakingly spin yarns and weave them into complex designs, creating fabrics of extraordinary artistry and quality. The modern textile industry was established by these pioneering methods.

Industrial Revolution and Textile Manufacturing:

Textile production faced a change when the Industrial change began in the 18th century. The invention of mechanized spinning and weaving devices, such as the spinning wheel and power loom, significantly increased manufacturing efficiency. The ability to produce textiles in large quantities contributed to the expansion of the global textile industry and the proliferation of textiles. The foundation for contemporary textile manufacture was laid during the Industrial Revolution, which saw a significant shift from manual labor to machine production.

Technological Advancements in Textile Manufacturing:

Further developments in textile production technologies occurred in the 20th century. Power looms and other automated equipment were introduced, which further improved the production process and increased the affordability and accessibility of textiles. Furthermore, the business was transformed by the introduction of synthetic fibers like polyester and nylon, which opened up new possibilities in terms of affordability, adaptability, and durability. In textile plants, automation spread more widely, enhancing productivity and efficiency.

Sustainable Textile Manufacturing Techniques:

The textile industry has placed a growing value on sustainability in recent years. Manufacturers are investigating recycling and upcycling methods to cut waste and lower their carbon footprint as concerns about the effects on the environment and the decreasing supply of resources grow. Furthermore, there is a rising market for environmentally friendly products including hemp, bamboo, and organic cotton. As customers place a higher value on socially produced goods, sustainable textile manufacturing techniques are both environmentally friendly and commercially successful.

Digitalization and Textile Manufacturing

The textile industry has also been impacted by the digital revolution. Textile design, production, and marketing have all undergone radical change thanks to computer-aided design (CAD) and manufacturing (CAM) technologies. Manufacturers may now optimize production processes for optimal efficiency and cost-effectiveness, while designers can now precisely and efficiently produce complex patterns and textures. Textile companies are experiencing even greater efficiency and quality control thanks to smart manufacturing processes made possible by devices and data analytics.

Future Trends in Textile Manufacturing:

Future developments in textile manufacturing should bring about much more innovation and progress. The industry could undergo another revolution because to emerging technologies like nanotechnology and smart textiles, which present new opportunities in terms of performance, sustainability, and usefulness. Artificial intelligence has the potential to significantly impact supply chain management and production process optimization. One thing is certain , as the textile business develops further, innovation is essential to staying ahead in a world that is changing quickly. Change is unavoidable.

Conclusion:

The development of textile manufacturing techniques is evidence of the inventiveness, flexibility, and creativity of people. Throughout the ages, the textile industry has experienced a remarkable transition, moving from its modest beginnings to the forefront of technical innovation. Looking ahead, there are countless opportunities. The textile sector has embraced innovation, digitization, and sustainability, and as a result, it is well-positioned to prosper going forward.

Researching Source: Google

Writer information:

Akhi Akter

Department of Textile Engineering (3rd Year)

Green University of Bangladesh