Below is an overview of the knitwear production process,accompanied by some illustrative visuals from our factory.

1.Yarn and Accessories Storage

2. Winding

3.Knitting Panel

4.Inspection

5.Linking

6.Trimming

7.Mending

8.Light Inspection

9.Washing

10.Sewing (includes labels, accessories, product quality control, and a light check post-washing)

11. Appearance and Moisture Level

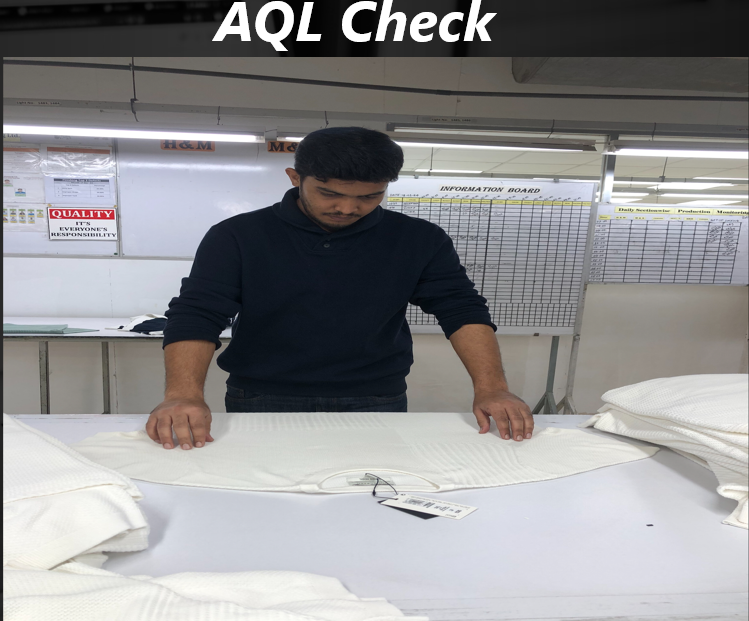

12. Inspection Acceptable Quality Level (AQL) Testing

13. Hang Tag Application and Metal Content Verification

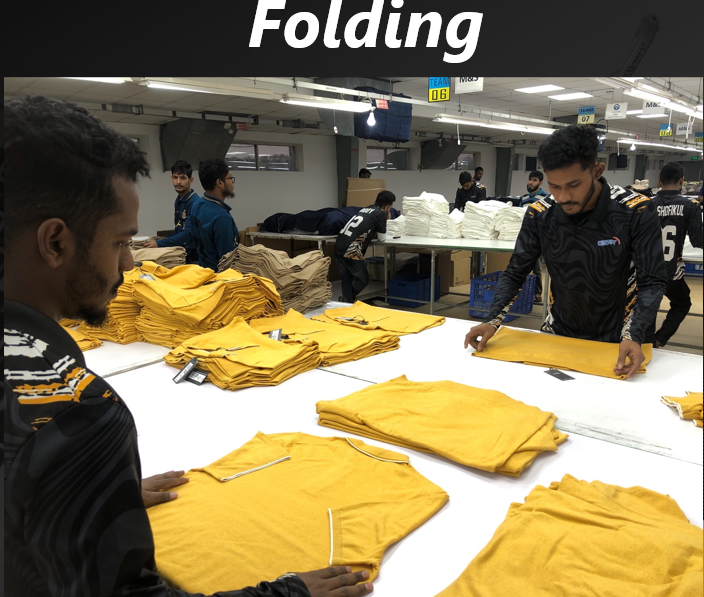

14.Folding, Packing, and Transfer to Warehouse

15 .Ex-Factory Dispatch

Yarn Storage

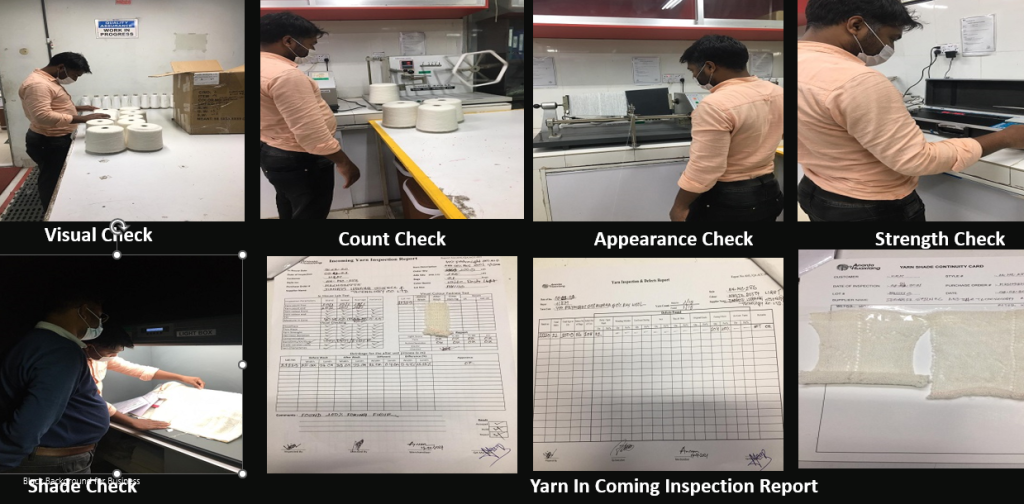

Yarn Inspection:

The initial step involves a visual inspection of the yarn, followed by a verification of the yarn count.Additionally, factory examine the yarn’s appearance, strength, and shade to ensure quality.

Winding :

Before knitting, the yarn must undergo winding, where it is transferred from large cones to smaller ones that fit into the knitting machine. This process also includes waxing the yarn to reduce friction and prevent breakage during knitting. Subsequently, the yarn is knitted into swatches to obtain final approval based on its appearance and other properties.

Knitting & Inspection on panel:

Once the knitting is completed on the machine, the panel undergoes a preliminary inspection.

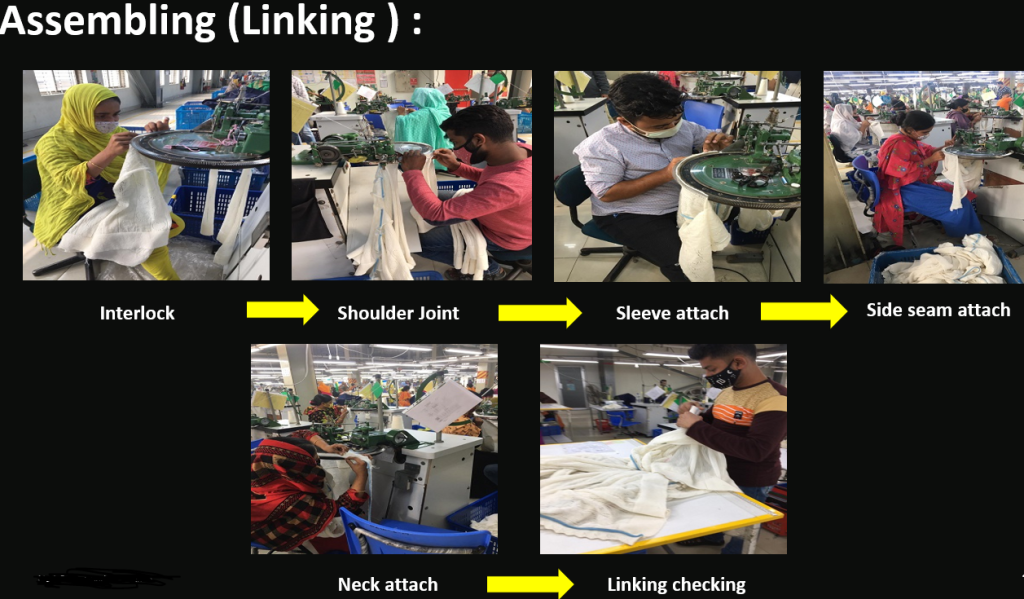

Linking/ Assembling:

After the knitting process, the next step is linking and assembling, typically conducted using a dial linking machine. This involves joining and assembling the shoulder, sleeve, side seam, and neck of the garments. Following the assembly, each linking area of the garments is inspected for quality.

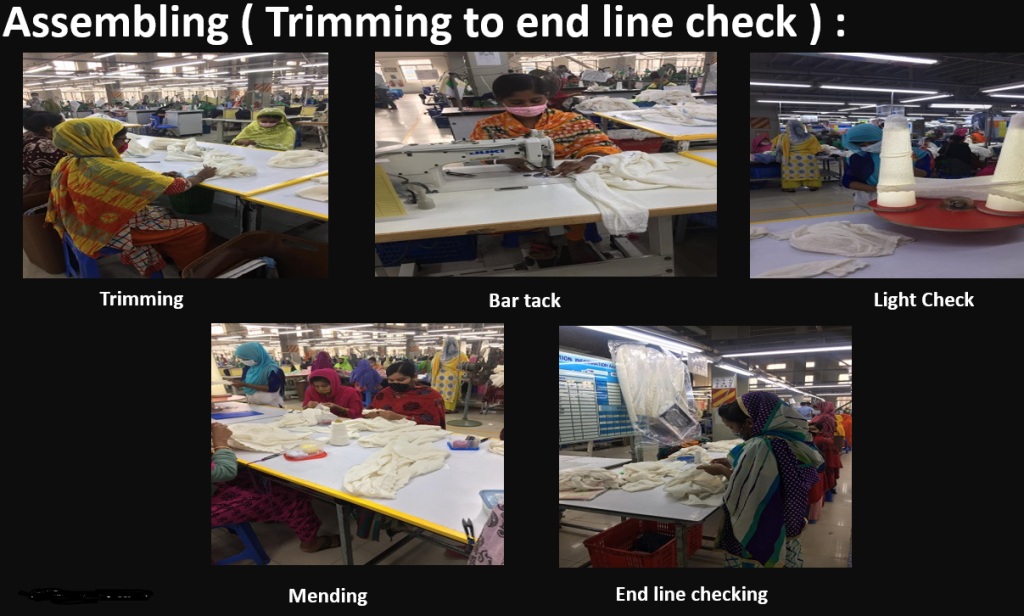

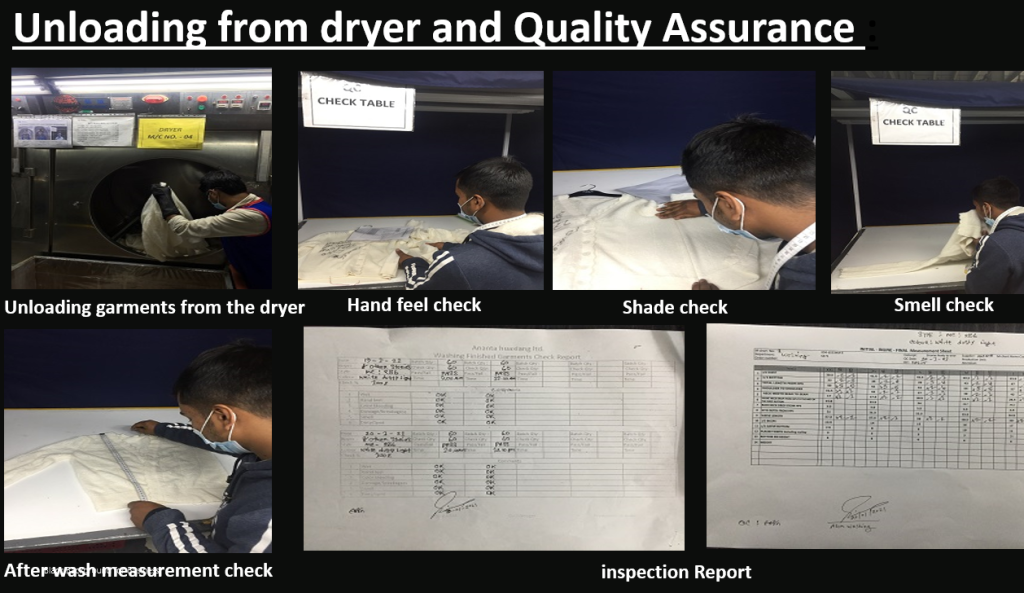

Following the assembly process, garments are trimmed and checked at the end line before being sent for washing. This is followed by careful monitoring of each step. After the washing and drying cycles, the garments are removed from the dryer and assessed for hand feel, measurements, and color consistency.

After washing, drying, and quality inspection, the garments are sent to the sewing section for the attachment of buttons, zippers, labels, or other accessories. Subsequently, a light check is conducted to identify any linking damage that may have occurred during washing .

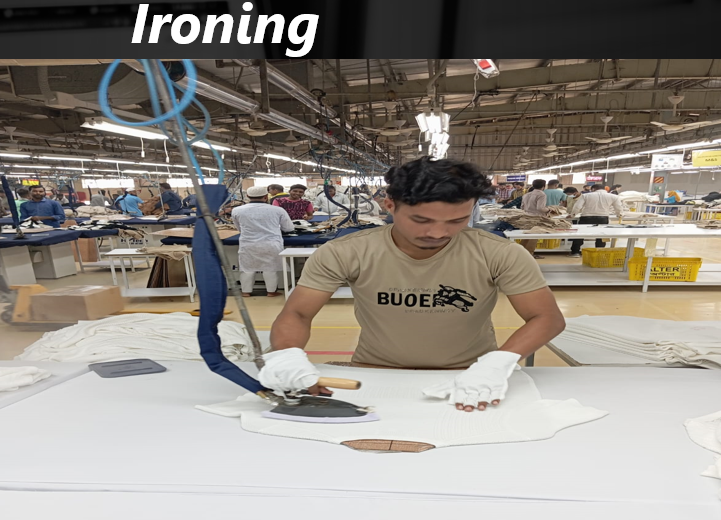

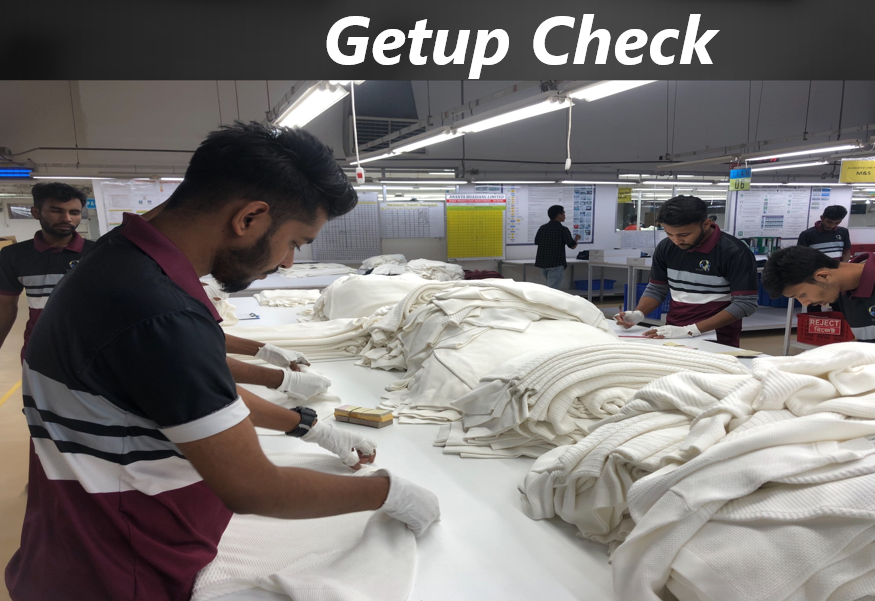

After completing all checks, garments are ironed on size-based patterned boards or structures to maintain desired measurements. The appearance is then inspected, and hangtags are attached. Next, an AQL check is performed, followed by a metal detection process. The garments are then folded and packed according to specific packing instructions and are placed in either cartons or hangers, depending on the selected modularity.

After packing, the goods are stored in the warehouse before being shipped from the factory to the port.

These are general processes for your reference.please note that there may be slight variations between factories and regions.

Writer Information:

Abdullah Al Mamun

Business Unit Manager

Marks & Spencer