Silk fiber, renowned for its unparalleled elegance and luxurious texture, has captivated human civilization for centuries. This exquisite natural fiber, with its rich history and diverse applications, continues to hold a special place in the world of textiles and beyond.

Silk Fiber

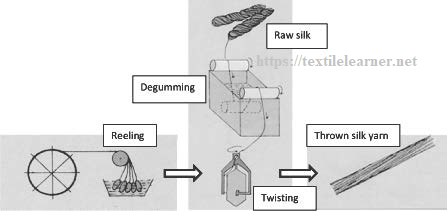

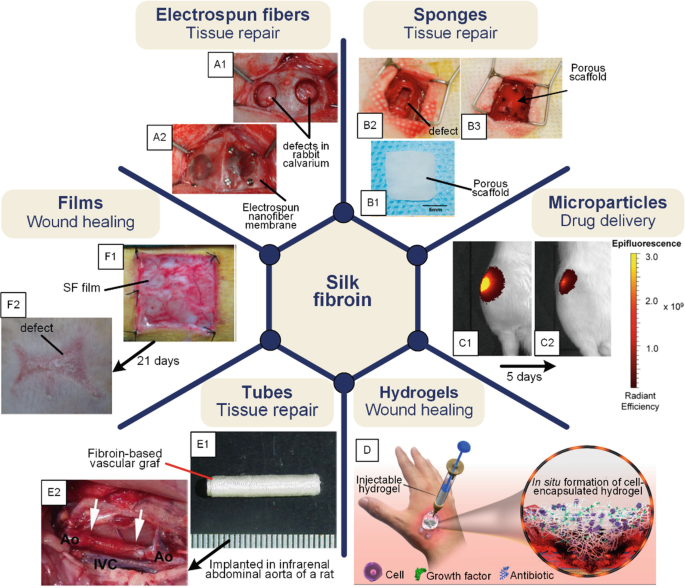

Silk fiber is a natural protein fiber produced by silkworms, primarily from the cocoons of the larvae of the Mulberry silkworm (Bombyx mori). The process of silk production, known as sericulture, involves carefully nurturing these silkworms to produce fine threads that are spun into silk. Unlike other natural fibers, silk has a unique luster and smoothness, making it exceptionally desirable in the textile industry.

Properties of Silk Fiber

Silk is celebrated for its strength, elasticity, and smooth texture. It is one of the strongest natural fibers, capable of withstanding significant tension. Silk’s protein structure allows it to be highly receptive to dyes, resulting in vibrant and long-lasting colors. Additionally, silk is biodegradable and hypoallergenic, making it an environmentally friendly and skin-friendly option. The fiber’s ability to regulate temperature also adds to its appeal, providing warmth in winter and coolness in summer.

Historical Context

Silk’s history dates back thousands of years, with its origins rooted in ancient China around 2700 BCE. The Silk Road, a network of trade routes established during the Han Dynasty, played a crucial role in spreading silk across continents, influencing cultures and economies along the way. This trade route facilitated not only the exchange of goods but also ideas, art, and knowledge between the East and West.

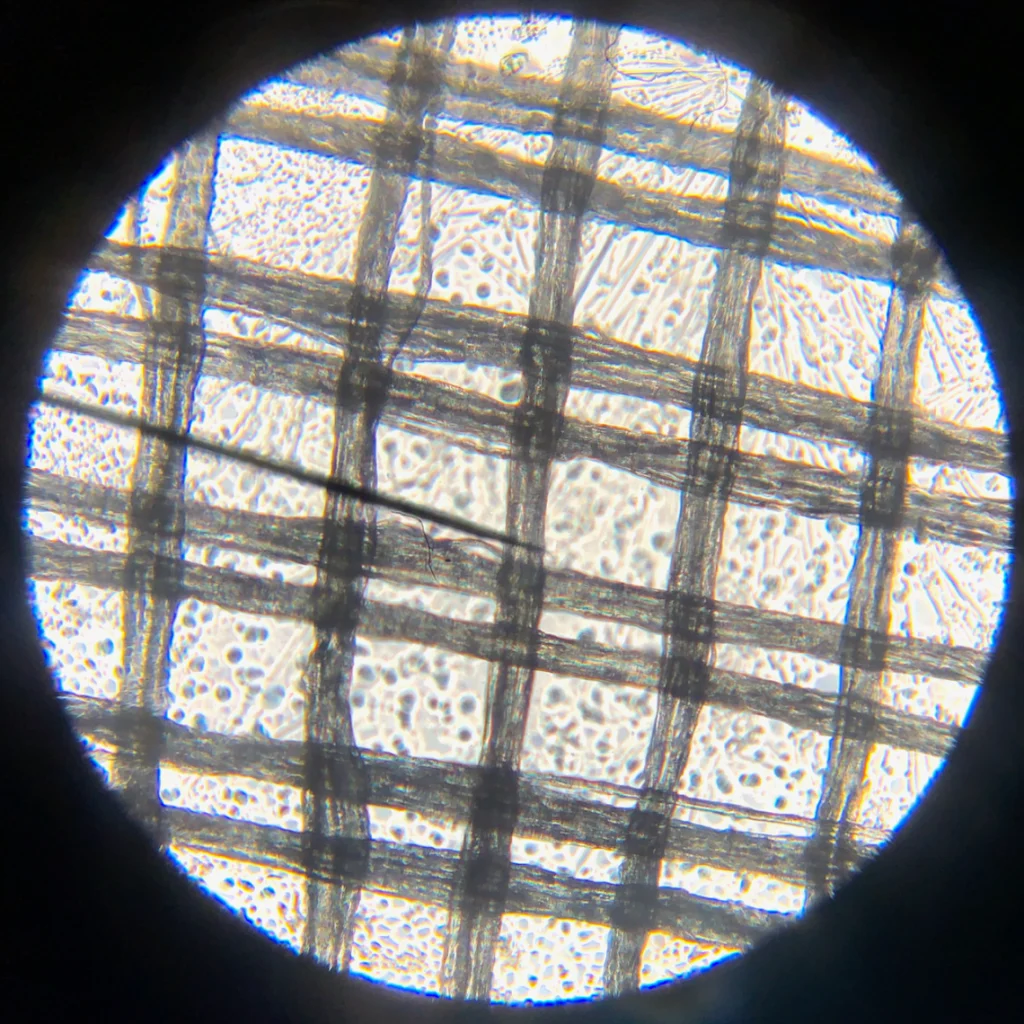

Silk Production Process

The journey from silkworm to silk fabric involves several meticulous steps. Silkworms are cultivated in controlled environments and fed mulberry leaves until they spin their cocoons. Once the cocoons are harvested, they are placed in hot water to soften the sericin (a natural gum), allowing the silk threads to be unwound. These threads are then spun into yarn and woven into fabric. The entire process demands precision and care, reflecting the craftsmanship involved in silk production.

Applications of Silk

Silk’s versatility extends beyond fashion. In the medical field, silk is used in sutures due to its biocompatibility and biodegradability. It’s also utilized in advanced applications such as tissue engineering and drug delivery systems. In cosmetics, silk proteins are added to products for their moisturizing and anti-aging properties. Its luxurious feel and natural sheen make it a preferred choice for high-end clothing, bedding, and home décor.

Silk Industry in Bangladesh

Bangladesh has a rich history of silk production, dating back to ancient times. Today, the country remains a significant player in the global silk industry. Regions such as Rajshahi and Jessore are renowned for their silk production, with Rajshahi often referred to as the “Silk City.” The Bangladesh Silk Development Board (BSDB) plays a pivotal role in supporting and promoting the industry through initiatives aimed at improving sericulture practices and expanding market reach.The silk industry in Bangladesh faces challenges such as competition from synthetic fibers and the need for technological advancements. However, initiatives by the government and success stories from local entrepreneurs highlight the potential for growth and innovation in this sector. With continued investment and modernization, Bangladesh’s silk industry could see significant expansion in the coming years.

Economic and Cultural Impact

The silk industry significantly contributes to the Bangladeshi economy, providing employment opportunities and fostering rural development. Thousands of families are involved in various stages of silk production, from sericulture to weaving and finishing. Culturally, silk holds a special place in traditional festivals and attire. The intricate Jamdani and Baluchari saris, made from silk, symbolize elegance and heritage, often worn during significant cultural and religious events.

Environmental and Ethical Considerations

While silk is a natural and biodegradable fiber, ethical concerns regarding the treatment of silkworms have been raised. Traditional sericulture involves boiling cocoons with the larvae inside to extract the silk thread, which raises animal welfare issues. Innovations such as Ahimsa silk, or peace silk, allow for the production of silk without harming the silkworms, addressing these ethical concerns. Additionally, sustainable practices in silk farming and manufacturing are being developed to minimize environmental impact, ensuring that silk remains a responsible choice.

Future Prospects

The future of silk production looks promising with advancements in biotechnology and materials science. Researchers are exploring ways to engineer stronger and more versatile silk fibers, potentially expanding their applications in various industries. In Bangladesh, continued support from the government and private sector, along with embracing modern technologies, can enhance productivity and global competitiveness. As the demand for sustainable and ethical textiles grows, Bangladesh’s silk industry is well-positioned to capitalize on these trends.

Conclusion

Silk fiber, with its timeless elegance and versatile applications, continues to be a cherished. There won’t be anytime soon that will reduce the popularity of Silk!

AUTHOR

MD. Gazzali Islam

Department of Textile Engineering

Ahsanullah University of Science and Technology